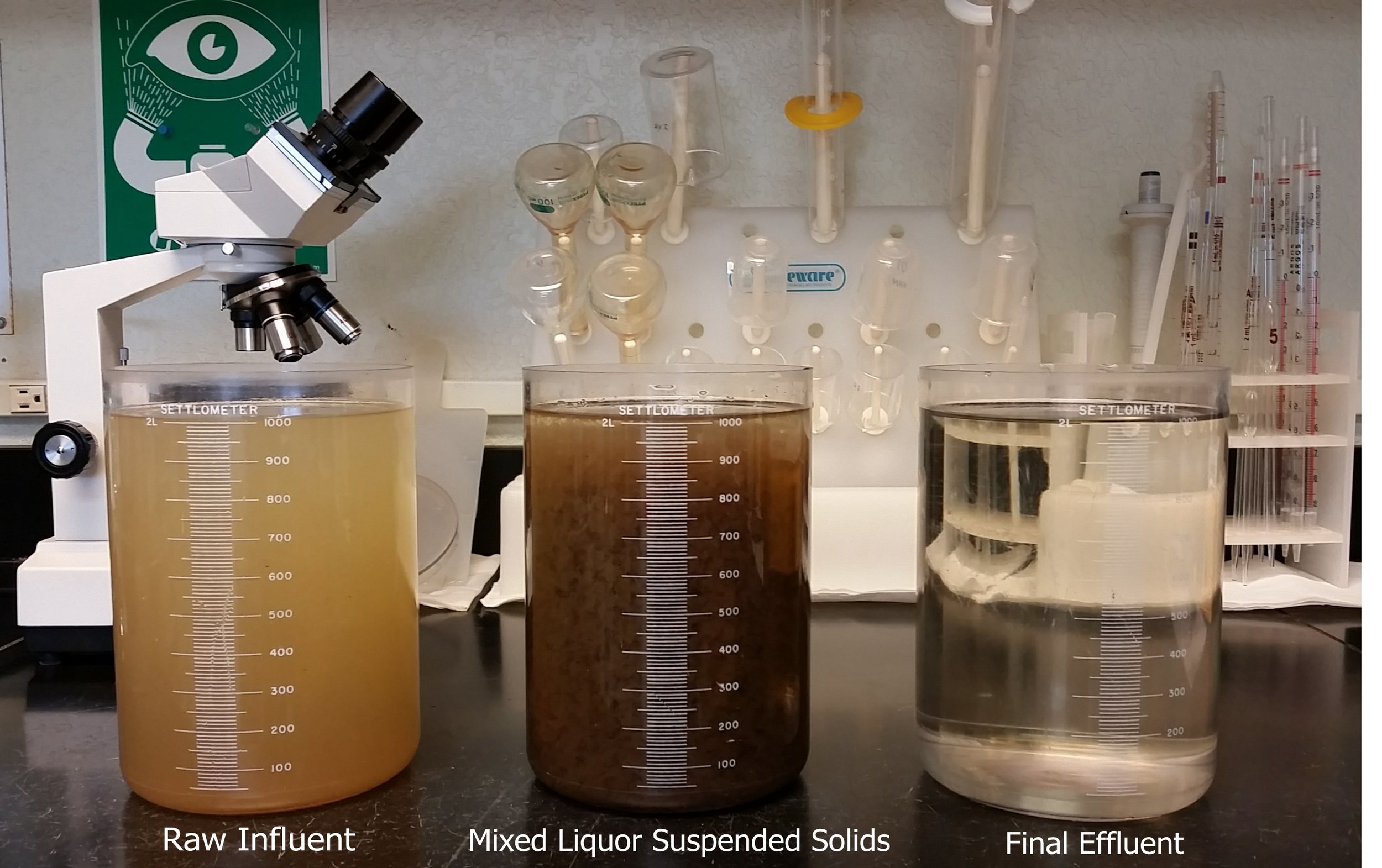

Since 2012, the Town has been in the water reclamation business. Operating two facilities, one in north Marana and one in the Rillito neighborhood, is the work of our Water Reclamation division. This staff of five work around the clock to ensure everything is functioning properly at these reclamation facilities. This work includes some extensive testing, monitoring, and reporting requirements. This week we highlight how much goes into keeping track of how well our water is being treated before it hits the aquifer.

Background

The Clean Water Act established in 1972, and substantially amended in 1987, regulates the physical, chemical, and biological integrity of the nation’s water. These regulations and protections of surface water are one of the primary regulatory drivers dictating treatment requirements at the Town of Marana’s Water Reclamation Facility. Additionally, the Water Pollution Control Act of 1948 provides the current framework for surface water quality regulation in the United States. When initially enacted, Clean Water Act worked to establish universal treatment nationwide using certain technology requirements. The 1987 amendments established water quality-based standards. To meet these new standards, advance treatment methods needed to be in place including, in many instances, nitrification/denitrification and enhanced disinfection, which further clean the water.

Marana Water Department’s Water Reclamation Division oversees the water quality and regulatory issues associated with its operations in efforts to meet the primary mission to protect public health and the environment. An extensive water quality program is administered through this division to perform surveillance sampling of its treatment facilities, analytical testing and documentation, and reporting of water quality.

The Town of Marana’s Water Reclamation Facility (WRF) operates under a variety of water quality permits including AZPDES, APP, and reuse permits. Each of these permits contains specific lists of contaminants that must be monitored and their prescribed monitoring frequencies. As a result, it is common for this facility to be subject to over 1,300 individual analyses per year to document and ensure water quality objectives are met.

These permits require the Water Reclamation staff to collect samples for the following things:

- Microbiology - E. Coli and total coliform (human and animal waste)

- General Chemistry – Ammonia, biochemical Oxygen Demand, Nitrate/Nitrite, Total Kjeldahl Nitrogen, Oil and Grease, Phosphorus

- Metals – approximately 17 metals including antimony, arsenic, and mercury

- Volatile Organic Compounds – approximately 28 types. These are chemicals that contain carbon and evaporate easily like solvents, cleaners, and pesticides.

- Semi-volatile compounds – approximately 11 types. These can be things like flame retardants and some pesticides.

- Toxicity – evaluates the potential harmful effects to the water system. Things like algae, flathead minnows and water fleas are used to track toxicity of the effluent.

Reporting Requirements

In 2016, the Water Reclamation division collected almost 1,300 samples. From these 1,300 samples, 85% were required for regulatory compliance. These 1,100 samples were individually analyzed and reported to the proper agency. The remaining 15% were collected for quality assurance and to monitor treatment processes and performance at the plant. The chart to the right shows how the regulatory structure works. Starting with the federal government and funneling down to the state Department of Environmental Quality, there are many entities ensuring we meet all the Clean Water Act standards.

There are schedules for sampling for compliance to ADEQ. These can be done quarterly or monthly depending on the test type. Each permit issued to our plant outlines these testing frequencies and our staff work hard each day to meet them. Those 1,300 samples are all done by hand by those operators. Most of the samples then head off to a lab where they will complete the sampling procedures. There are some tests that are time- and temperature-sensitive, so these tests are done by our staff in a small on-site lab. Additionally, the water discharged at the end of the treatment process needs to be tested. The discharge water is held to high standards as well, and even requires an authorized representative to sign each report. There is language in the law that says they agree that the information is “true, accurate, and complete” and that there are fines up to $27,500 or 5 years in prison for knowingly submitting false information.

What happens if there is a failure? Our staff have to notify the state by 9:00am the following day after a failure has happened. A failure can be missing a required sample, monitoring at the wrong frequency, not submitting results in the required time frame, or exceeding the maximum level for a contaminant. Our team has an extremely low failure rate, even having to collect so many samples. Should one of these events occur, there are established Regulatory Compliance Response steps in place that we would have to follow. This can include notifying the permitting authority and treatment personnel, and increased sampling frequency after a comprehensive investigation and audit. Once the failure has been corrected the facility is back in compliance and after-action reports and training are conducted.

As you can imagine, there is specialized training to work in the water reclamation world. Our staff have Wastewater operator certifications as well as additional training in proper sample collection procedures, chemistry, reporting structures, and much more. Their attention to detail is second to none.

These testing requirements are a necessity in the water reclamation world to ensure water quality and protect public health. This is one of the largest portions of the water reclamation budget. For the 2016 fiscal year the total budget for sampling and testing requirements was almost $140,000. Having the proper permits issued is 11%, laboratory analysis is 40%, and the remaining 49% covers all the materials and administration of the program.

Our water reclamation staff are a small and strong group. Maintaining the wastewater treatment facility, ensuring all permits and testing schedules are up to date, and additional general day-to-day operations are all vital to the success of our treatment facility. The effluent water that they produce, at a high quality, goes back into our aquifer to be recharged for future water use. The quality of this water is important to ensuring we have a safe future water supply. They are an integral part of our mission to provide safe and reliable water.

Want to keep up with the happenings with Marana Water? Click the Sign Up button below.